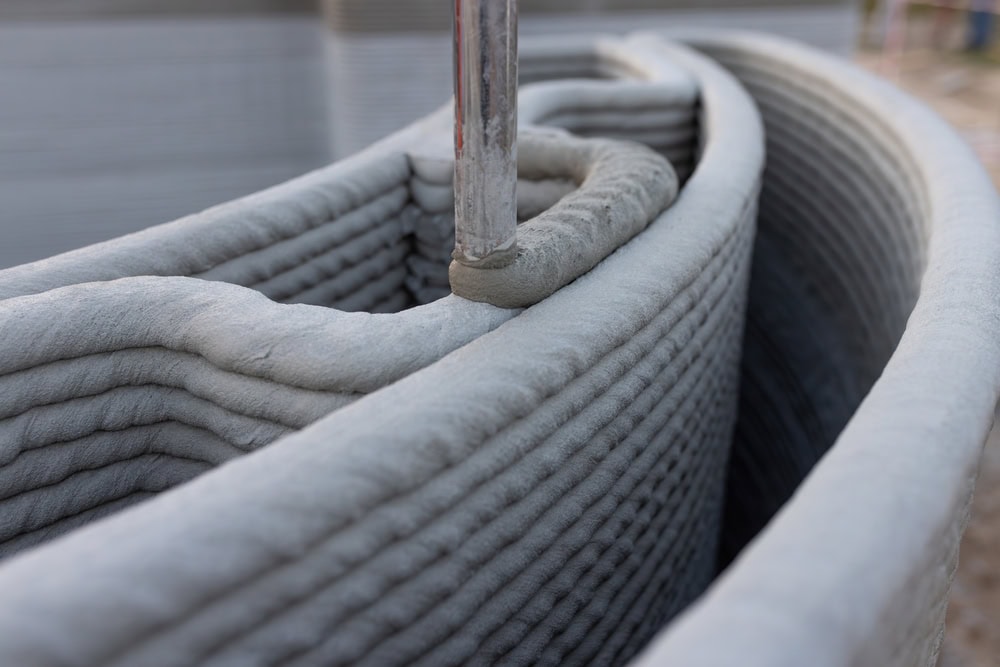

The construction industry is witnessing a revolutionary shift as 3D printing technology continues to gain traction. Also known as additive manufacturing, 3D printing involves creating three-dimensional objects by adding successive layers of material based on a digital model. This innovative technology presents both exciting opportunities and challenges for contractors in the construction sector.

Opportunities:

- Complex and Customized Designs: One of the most significant advantages of 3D printing in construction is the ability to create highly complex and customized designs that would be difficult or even impossible to achieve through traditional construction methods. With 3D printing, architects and engineers have the freedom to explore unconventional shapes, intricate geometries, and unique structural elements, pushing the boundaries of architectural creativity and innovation.

- Reduced Construction Time: Traditional construction methods often involve lengthy lead times for material procurement, transportation, and on-site assembly. However, with 3D printing, many components can be manufactured on-demand and on-site, significantly reducing construction times and minimizing delays caused by supply chain disruptions.

Waste Reduction and Sustainability: The construction industry is known for generating substantial amounts of waste due to material offcuts, inefficient use of resources, and demolition debris. 3D printing offers a more sustainable approach by producing components with a high degree of precision, minimizing material waste, and promoting resource efficiency. - Customization and Localized Production: 3D printing allows for localized production, enabling contractors to manufacture components and structures tailored to specific project requirements. This level of customization can lead to cost savings, reduced transportation needs, and a more efficient construction process overall.

Challenges:

- Regulatory Considerations: Building codes and regulations may need to be updated to accommodate the use of 3D printed structures, ensuring they meet safety and performance standards. Contractors and regulatory bodies will need to collaborate closely to establish guidelines and certification processes for 3D printed construction components and structures.

- Material and Equipment Costs: While the technology is becoming more accessible, the initial investment required for specialized 3D printing equipment and materials can be a barrier for some contractors, particularly smaller firms. The cost of materials suitable for large-scale 3D printing in construction may also be higher than traditional materials, at least initially.

- Training and Expertise: Contractors and their teams will need to acquire new skills and knowledge to effectively design, operate, and maintain 3D printing systems. This may require significant investment in training programs and the development of educational resources specific to the construction industry.

- Scale and Speed Limitations: While 3D printing can offer advantages for certain components and structures, there are limitations in terms of scale and speed when it comes to large-scale construction projects. Some projects may require a combination of traditional and 3D printing methods to achieve the desired results within reasonable timeframes.

Despite these challenges, the construction industry is already witnessing successful implementations of 3D printing technology. For example, in 2019, a family in Williamsburg, Virginia, moved into the world’s first 3D-printed residential home. The 1,550-square-foot house was constructed using a concrete 3D printer, demonstrating the viability of this technology for residential construction.

Another notable example is the 3D-printed housing project in Austin, Texas, where a company called ICON has developed a proprietary 3D printing technology to create affordable and resilient housing. They have successfully printed several homes using a concrete-based material, showcasing the potential for 3D printing to address housing shortages and provide sustainable construction solutions.

As the technology continues to evolve and become more accessible, it is expected that more contractors will embrace 3D printing as a way to enhance efficiency, reduce waste, and unlock new design possibilities in the construction industry. However, addressing the challenges associated with regulation, costs, and training will be crucial for the successful integration of 3D printing into mainstream construction practices.

Here are the resources with links for contractors to learn more about 3D printing in construction:

Industry Associations and Organizations:

- Associated General Contractors of America (AGC)

- American Concrete Institute (ACI)

- Additive Construction Association

Educational Institutions and Programs:

- Georgia Institute of Technology Digital Building Construction program

- Coursera online courses

- edX online courses

- Udemy online courses

Trade Shows and Conferences:

Online Resources and Publications:

- Construction Executive

- Engineering News-Record (ENR)

- For Construction Pros

- 3DPrint.com

- 3D Printing Industry

- 3D Printing Media Network

Manufacturer and Vendor Resources: